lab reportr hardness testing|vickers hardness test formula : makers The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an . Here at Consolidated Sterilizer Systems, we’re of the mind that the importance of routine preventative autoclave maintenance really can’t be understated. Bearing that in mind, we’ve put together this free sterilizer maintenance log .

{plog:ftitle_list}

In this video, you'll learn how to autoclave your Eppendorf Research pipette for easy decontamination. Being highly durable and robust, many Research pipette.

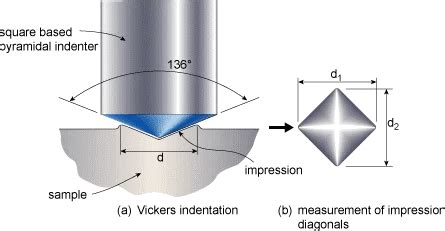

The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess a material's hardness.The hardness test is performed to determine the suitability of a material for a given applicatio.The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an .The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess a material's hardness.

The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens and harder material.

PURPOSE. The purpose of this exercise is to obtain a number of experimental results important for the characterization of the mechanical properties and performance of materials. The hardness test is a mechanical test for material properties which are used in engineering design, analysis of structures, and materials development.TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

describe autoclaving process

(III) Theory: The Brinell Hardness Test is used to determine the Hardness Number of hard, moderately hard, and soft material E.g.: Brass, Br onze, Aluminum, Gold, and Copper.

PDF | This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test | Find, read and cite all the research you need on.This module provides a classroom lesson and a lab experiment for measurement of hardenability in a high-carbon steel according to, the Jominy End-Quench Test , (ASTM A255 – 10).When you require precise measurements for materials with high hardness or thin coatings – the Vickers hardness test is suitable. When needing to perform hardness testing on-site or non-destructively – the Leeb hardness test provides portability and convenience.

2. HARDNESS TESTING THEORY. Hardness is usually defined as the resistance of a material to plastic penetration of its surface. There are three main types of tests used to determine hardness: • Scratch tests are the simplest form of hardness tests. In this test, various materials are rated on their ability to scratch one another. Mohs hardness .

Lab report - Have students report, presenting their results and discussing any variables involved in differences in measurements and literature in order to reiterate the key concepts involved in hardness evaluation for materials.The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess a material's hardness.The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens and harder material.PURPOSE. The purpose of this exercise is to obtain a number of experimental results important for the characterization of the mechanical properties and performance of materials. The hardness test is a mechanical test for material properties which are used in engineering design, analysis of structures, and materials development.

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 . (III) Theory: The Brinell Hardness Test is used to determine the Hardness Number of hard, moderately hard, and soft material E.g.: Brass, Br onze, Aluminum, Gold, and Copper.

PDF | This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test | Find, read and cite all the research you need on.This module provides a classroom lesson and a lab experiment for measurement of hardenability in a high-carbon steel according to, the Jominy End-Quench Test , (ASTM A255 – 10).When you require precise measurements for materials with high hardness or thin coatings – the Vickers hardness test is suitable. When needing to perform hardness testing on-site or non-destructively – the Leeb hardness test provides portability and convenience.2. HARDNESS TESTING THEORY. Hardness is usually defined as the resistance of a material to plastic penetration of its surface. There are three main types of tests used to determine hardness: • Scratch tests are the simplest form of hardness tests. In this test, various materials are rated on their ability to scratch one another. Mohs hardness .

describe the use of an autoclave in microbiology laboratory

describe why chemical sterilization might be used instead of autoclaving.

vickers hardness test procedure pdf

In this blog we’ll tackle the concept of thermal mass as it relates to sterilization, and a couple of autoclave features that can save time and money on your liquid loads. First let’s talk about thermal mass and load lag.

lab reportr hardness testing|vickers hardness test formula